Process Improvement

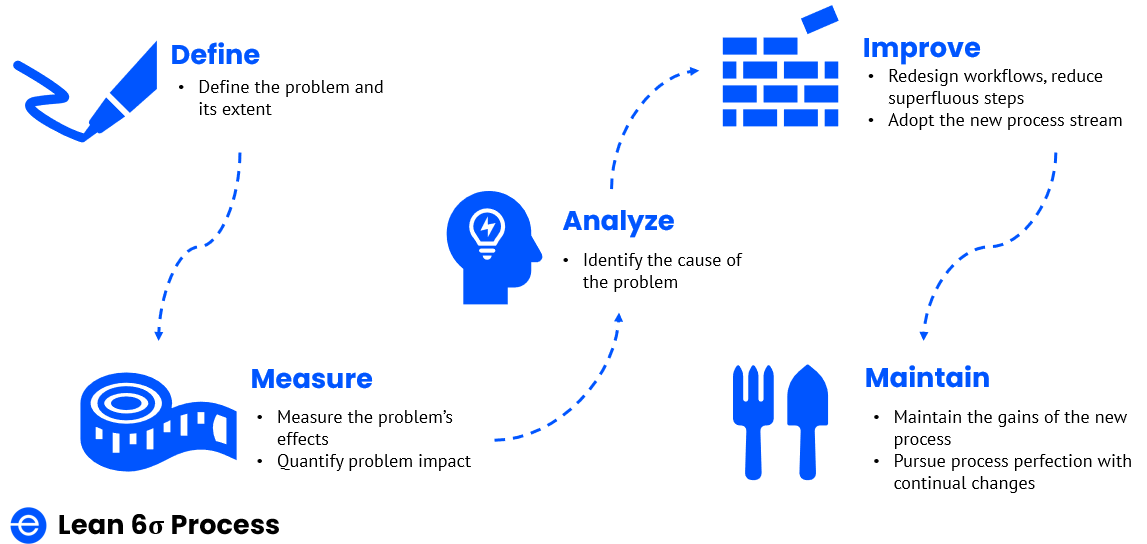

Get a clear path to achieving your process improvement goals through Lean and Six-Sigma methodologies.

Enterey utilizes Lean and Six-Sigma methodologies to provide organizations with a clear path to achieving their process improvement goals.

Example Case Studies

Facility Transfer

Our client anticipated rapid growth of operations and had plans to move to a significantly larger facility. They were aware that, in order to achieve the expanded scale necessary to operate the new facility, they must improve existing business processes and eliminate inefficiencies. This process improvement the goal of the project.

Discovery & Design

Enterey was brought on-board to identify ways to improve existing business processes in order to acclimate to the expanded scale of their new facility.

Implementation

Enterey consultants facilitated collaborative sessions with client stakeholders, identifying projects and scoping a phase-gate approach to enable the company to achieve the necessary process improvement in alignment with the facility construction timeline. Our team supported the creation of a Project Management Office (PMO) to establish governance and organization to all the projects.

Results Achieved

Our client successfully kicked off fifteen projects during the first phase of this program. The establishment of the PMO enabled monitoring progress and issues of each project, and regularly reporting on their status to the Steering Committee. Over $2M of efficiencies were identified during the first phase of the program.

Partner Collaborations

Our client was collaborating with multiple partner companies to test combination therapies in clinical studies. Due to the lack of a robust business process to integrate partner documents and data into their regulatory, manufacturing and distribution systems, our client experienced delays to supply for trials. They identified a primary goal as minimizing disruptions to mitigate delays in supply.

Discovery & Design

Enterey was brought in to assist with the process of partner collaboration in order to minimize disruptions in supply and allow for smoother operations going into clinical trials.

Implementation

Enterey consultants quickly identified the pain points and focused on Planning, Quality and Regulatory to address these issues. In addition to completing an end-to-end process map linking the required documentation to the systems, our team also built a project management tool that ensured visibility to where all Partner Collaboration project stood with relation to supply.

Results Achieved

Our Client has leveraged this process since then, to prevent any supply disruptions. The Client also benefited from the improvement in their relationships with Partners, due to better communication around documentation requirements.

-1.png?width=266&height=69&name=Enterey_Color-Logo-withTag%20(1)-1.png)